May 18, 2018 Update

Our commitment to get this finished has never wavered, but our communication has! We are targeting shipping finished pieces in late June or early July, and here is more detail as to what has been going on since the last update.

In mid-November we lost access to both the CNC mill and vacuum former that we had been using all along, and getting access to different equipment has been a challenge – but we now have a firm plan in place and we are just about there. We had been using TechShop – a maker space – for much of our prototyping needs, frequently using the CNC mill, vacuum former, water jet, Bridgeport mill, lathe, and other equipment that we don’t own ourselves. TechShop closed down in November and we were left scrambling to find similar access to such equipment.

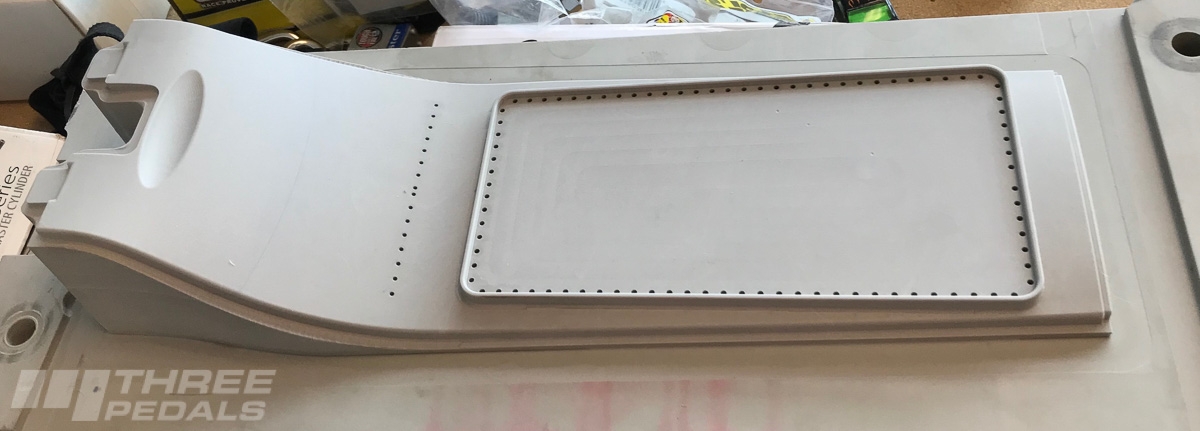

We are now up and running on a different CNC mill and have carved the third (and ideally final) mold for the ’96 Impala console insert, pictured above. We are getting our own vacuum former and expect to have that up and running in June. And then, we form away.

The delays have annoyed us and most certainly have annoyed you and for that we apologize. We are thrilled to finally have a viable solution to get these consoles finished and we remain confident that the finished product will be to your liking.

November 16, 2017 Update

The second version of the mold moved us from 90ish% on target to 97ish% on target. We obsess over the details and know you’ll appreciate when we hit this 100% and we are just about there. Our engineer is working on these last remaining tweaks and we expect the third try to be the final. We are planning on cutting the third mold the week of November 27th but this may slip to the week of December 11th. Once the mold is finalized, production and shipment should occur within a week or two.

The week of December 4th is a company holiday of sorts, so please excuse our absence. We will be in Indianapolis at the PRI show, where our wagon will be on display in Exedy’s booth. This a pretty big deal for us 🙂

Here are pictures of the second mold and the formed test insert. Note that the final inserts will not be glossy as the test one is, they will be a satin finish matching the console.

We are cutting the mold on a Haas CNC vertical mill. The inserts are then vacuum formed over this mold. After forming, the inserts are cut out on the Haas mill, using the mold as the fixture. Precision!

The final version will better fit inside the console – you can see it is currently slightly too wide in the front and at the rear it needs to slide back a bit more. Also, the gap between the formed piece and the console trim is inconsistent along the rear side edge. We had to do some iterating as we learned the way the vacuum forming process differs from the actual 3D part – stretching a 0.063″ thick sheet of melting plastic doesn’t wrap super tightly around inside corners. But we’ve got the translation just about dialed in.

Thank you for your patience! We have made serious progress over the last couple of months and now have great momentum going forward.

Interesting links

Here are some interesting links for you! Enjoy your stay :)Pages

- Big Brake Kits

- Clutch Play

- Factory Seconds

- Our Builds

- Shift Knobs

- Shop

- Wholesale Login

- Wholesale Store

- Dakota Digital HDX Instrument System Specifications

- Dakota Digital RTX Instrument System Specifications

- Dakota Digital VHX Instrument System Specifications

- Dakota Digital VFD Instrument System Specifications

- Jobs

- Pedals & Drivetrain Swaps

- Trucks

- New Products

- SSubtle Take

- Welcome to Three Pedals!

- Car API

- Events

- 1996 Impala Console

- G-Body Request a Quote

- Request a Quote

- Shaken & Stirred

- Car Craft Malibu

- Car Craft Malibu Build Products

- Conversion Kits

- Products

- Shop Online

- Rides Gallery

- About Us

- Services

- Blog

- Contact

- Info

- Cart

- Shipping & Returns

- Privacy Policy

- Terms of Use

- Checkout

- My Account

- Vehicle Search

- Cart

Categories

- 1961 Impala

- 1973 Oldsmobile Cutlass

- 1977 Mercedes 6.9

- 1977 Toyota FJ40

- 1988 Cutlass

- 1989 Pontiac Safari

- 1991 Jeep Wrangler

- 1992 Land Rover D90

- 1995 Caprice 9C1 6 Speed

- 1995 Chevrolet Impala SS

- 1996 Impala Gen V LT1

- 2007 BMW 328xi

- 2012 Dodge Charger SRT8

- 2015 Chevy SS

- 2015 Mustang GT

- 2017 Jeep Rubicon Recon Unlimited

- 2017 Toyota Tacoma

- 499HP Caprice

- About Press

- Blog

- CC/Malibu

- CC/Malibu Blog

- CC/Malibu Video

- FAQ

- Press

- Projects

- Shaken Blog

- Shaken Cool Kids

- Shaken Press

- Shaken Video

- T56 Teardown

- Technical

- Three Pedals #14

- Three Pedals #16